Environmentally friendly Jeans washing with the E-flow process

Mar 20, 2024

Last year we switched our jeans manufacturing to a revolutionary technology that allows us to drastically reduce water consumption.

As a market participant in a water-intensive industry, we understand the importance of clean water as one of our most vital resources. Therefore, we constantly strive to save water and use this precious raw material responsibly.

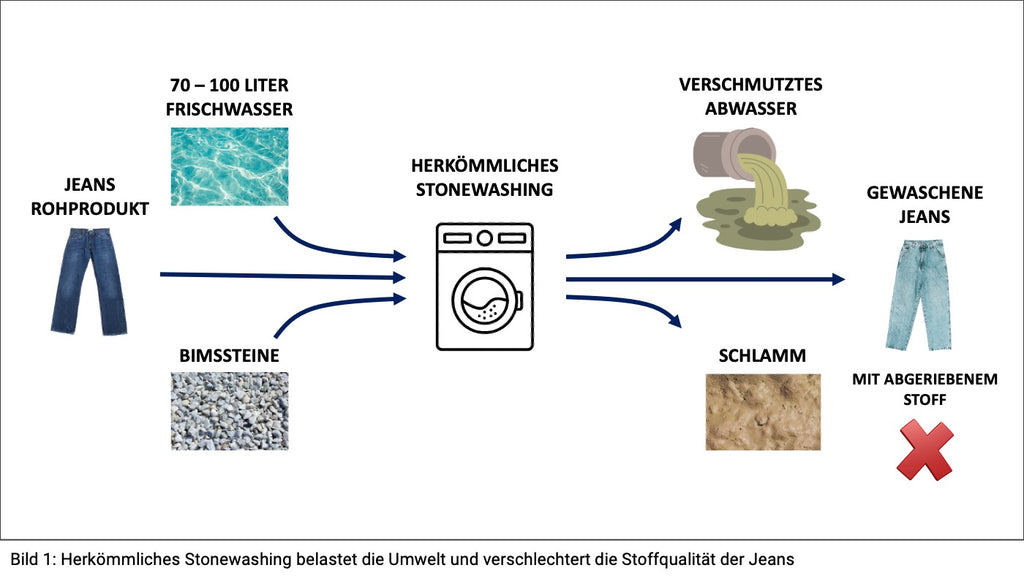

The traditional production and washing of jeans usually requires large amounts of water, chemicals and energy to achieve the desired washing effects. The best known method of washing jeans is stone washing, where the jeans are washed using stones or sand. This process aims to create a worn and washed-out look. The jeans are washed in large drums with stones or sand, which lightens the fabric and creates a casual used effect. However, the friction damages the surface of the fabric, uses a lot of water and creates large amounts of sand and mud that are washed out with the water. The mud can have harmful effects on the environment, including soil and water pollution and the impairment of ecosystems.

For 30 years now, the Spanish technology company Jeanologia has been researching technologies and solutions for more sustainable production in the textile industry. They helped develop a washing process called E-Flow and manufacture the washing drums required for it.

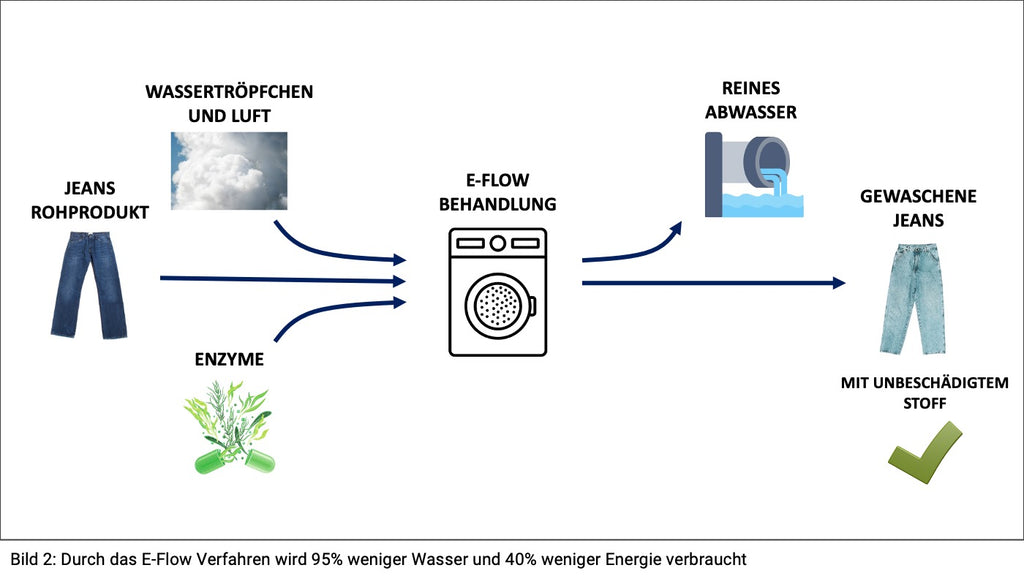

E-Flow technology uses steam instead of water. The jeans are treated in large drums in a steam mixture. Nano water bubbles apply the reactive substances to the fabric in low concentrations. Enzymes are usually used, which react with the dye and the cotton to achieve the desired effect. Enzymes have the advantage of being highly reactive and yet biodegradable.

This biotechnology means that no environmentally harmful substances end up in the wastewater. In addition, the E-Flow process can reduce water consumption by up to 95% and energy consumption by almost 40%. Another advantage is that the jeans are treated much more gently, which extends their lifespan.

Our jeans manufacturer SARP in Izmir has prepared and scaled the E-Flow technology for industrial application with the support of Jeanologia. The processes are being further refined and tested in a test laboratory.

We are proud to have gained access to this technology. Since 2023, all TORLAND jeans have been manufactured using this innovative and sustainable washing process. This allows us to significantly minimize the environmental impact and also significantly extend the lifespan and quality of the jeans.

Sources:

https://www.jeanologia.com/garment/eflow/